Product Details

Development History:

TB-Bushings(short for Taper Lock Bushings) was designed and introduced in the 1970s. By achieving secure and easy

installation between bore and the shaft, they were used to replace the traditional bore to size products as a relatively

new type of connection method. This product was then applied for patents in Europe, the US, Japan as well as the rest

of the world, with the patent protection lasting until the mid-1980s.

Taper bushing were gradually popularized and applied to various shaft to output conne-ctions, such as sprockets,

sheaves, couplings, timing pulleys and other transmission parts. The increased usage throughout the industrial market

boosted the standardization and commercialization of this product and turned it into a highly successful standardized

industrial component.

In the mid-to-late 1980s, along with the reform and opening pohc1es 1n China and with the rising production cost in

Europe, many European firms took the initiative to source high-quality and low-cost transmission parts from China to

export to the European market.

In 1986, Shijiazhuang Sprocket General Factory (CHSSB) began serial production of sprockets and other power

transmission components for the export market. In 1989, CHSSB took the initiative in producing TB bushings for export

to Europe, eventually achieving an annual production capacity of 500,000 sets. In 1994, CHSSB was responsible for

drafting the original "Taper Bushing Type, Main Dimensions and Basic Paramet -ers" Machinery Industry Standard of the

People's Republic of China (JB/T 7513-1994), which was approved and implemented by the Ministry of Machinery Industry

of China in October 1994.

In 2015, CAPT Power Transmission Co., Ltd. (CAPT), became responsible for drafting the JB bushing standard, and made

comprehensive revisions to the JB/T 7513-1994 "Taper Bushing Type, Main Dimensions and Basic Parameters" in accordance

with the relevant requirements of GB national standards. This included requirements and regulations for the application and

quality control of taper bushings. The National Standard of the People's Republic of China GB/T 32220-2015 was officially

iss -ued in 2015 by General Administration of Technical Supervision and Technical Standards Committee of the People's

Republic of China and officially implemented on July 1, 2016.

Advantage of CAPT:

CAPT Power Transmission Co. , Ltd. (CAPT) has a history of more than 30 years in producing the full range of steel TB

bushings, which are produced in strict accordance with international (DIN, ANSI, ISO, etc.) and domestic (GB) standards.

The products are of the highest quality, manufactured with precision equipment and reliable materials , becoming a leading

supplier in the international and domestic markets.

Adhering to the core concept of "Superior Ingenuity" , in the past 30 years CAPT has made significant investments in refining

the production process by using intelligent production systems and equipment to improve efficiency and reduce costs. Fast

and flexible production can be carried out according to customer demands to achieve the ultimate combination of precision,

reliability, and cost effectiveness.

Quality Characteristics:

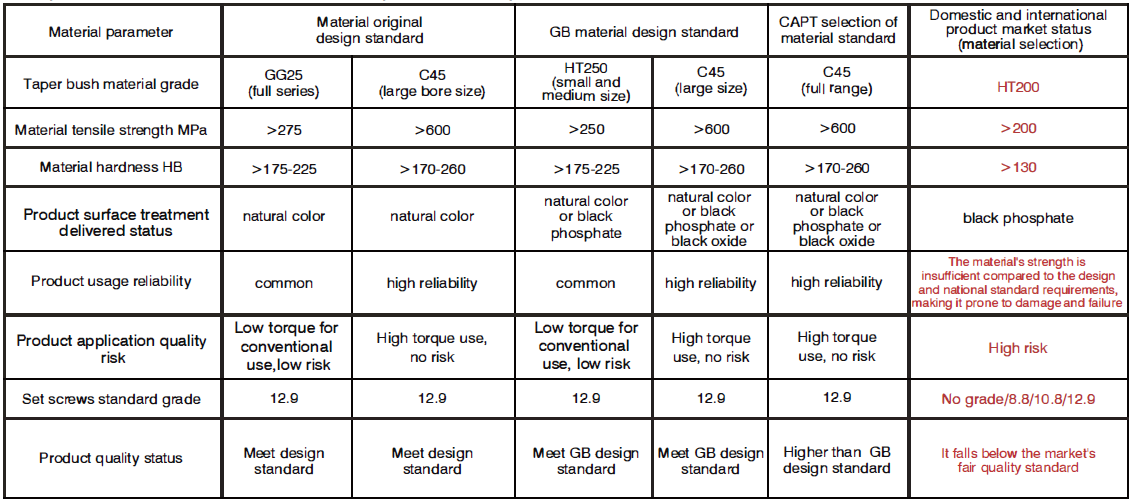

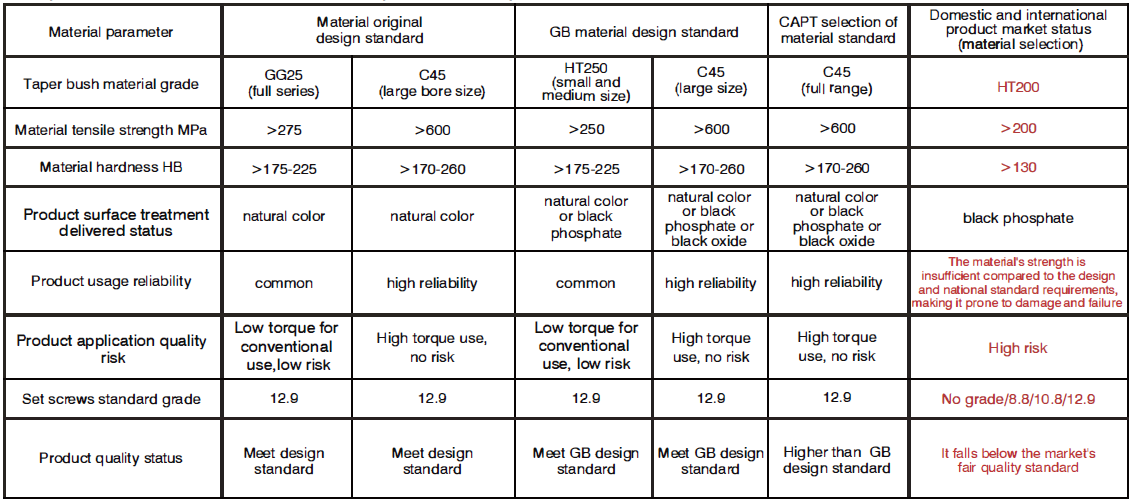

1. Material directly affects the strength and reliability of the product. Because the working principle of the taper bushings is

to lock the taper surface with the tightening screws, insufficient strength of the main body material will lead to cracking or

even damaging the taper surface and thread (commonly known as thread slipping/ stripping). Insufficient main body strength

can also damage the keyway during connection to the shaft due to the same reason (commonly known as rolling key) and the

product will ultimately fail.

Chinese GB National Standard: Main body material of taper bushing is C45 steel (Mpa>600) and grey cast iron HT250 (Mpa>250).

CAPT Standard: Main body material of taper bushing 1s C45 steel (Mpa>600).

Normal market standard: Main body material is grey cast iron HT200 (Mpa>200) which has low strength and does not meet

Chinese GB national standard or international standards.

2. The following are the main factors that affect installation, usage, and failures: differences in product manufacturing technique

and quality control standards on bore size, mounting screw holes and keyway accuracy.

3. The tightening screws used for the taper bushes are also key accessories. The connection between the taper bushing, the shaft

and the bore depends entirely on the tightening force generated by the screw, so that the shaft, the bore and the keyway can be

connected reliably. Therefore, the GB national standard clearly stipulates the torque requirements of the screw (grade 12.9).

Chinese GB National Standard: Screw grade 12.9.

CAPT Standard:Source g『ade 12.9 screws internationally with clear identification markings.

Normal market standard: To save cost, the screw quality fluct -uates between grade 8.8 to grade 12.9 without appropriate

identification markings.

Screw grade and material list:

Grade 8.8 screws: C45 steel;

Grade 10.8 screws: 40Cr;

Grade 12.9 screws: 42CrMo.

Material Comparison:

Product range:

Standards | Series Type | SizeRange |

DIN | 1008 | 10-25 |

1180 | 10-28 |

1210 | 11-32 |

1215 | 11-32 |

1310 | 24-35 |

1610 | 14-42 |

1615 | 14-42 |

2012 | 18-50 |

2517 | 20-60 |

2525 | 20-60 |

3020 | 25-75 |

3030 | 25-75 |

3535 | 35-90 |

4040 | 25-75 |

4545 | 55-110 |

5050 | 60-125 |

DIN Catalog: DIN BTL Taper Bushings-A series.pdf

DIN BTL Taper Bushings-A series.pdf